Lighting can cause UV damage to electric cables – is a new standard needed?

The insulation of electric cables used outdoors is well known to be prone to rapid degradation by ultra-violet (UV) exposure, so it is important that a type recommended for outdoor use be used. What is less well-known is that, even indoor cables, if mounted near to lighting systems (such as luminaires), can suffer from UV damage. The British Approvals Service for Electric Cables (BASEC), has just warned about this, as James Hunt reports:

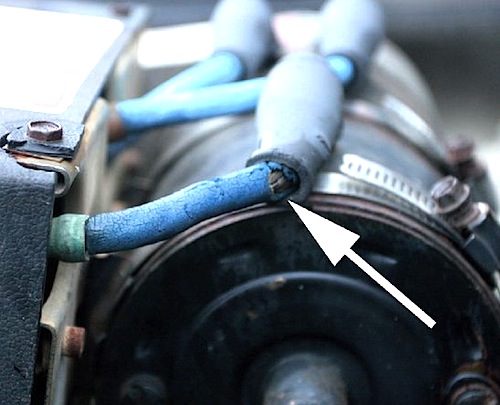

BASEC warns that it has seen examples of electric cables where the insulation on some low smoke halogen free (LSHF) cabling fitted close to a light source has become prematurely brittle, suffered cracks and in some cases fallen away exposing the conductor beneath as little as five years after installation in a non-domestic situation.

The organisation says that these observed effects are not limited to UK installations, but have also been observed in Germany and Scandinavia, and it poses the question: ‘are architects and designers correctly specifying suitable products to minimise this problem?’

That cables mounted or used outdoors are prone to very rapid degradation by UV exposure, has been known for decades, and it is important that a suitable type is recommended for outdoor use. Generally, says BASEC, UV degradation encountered in an office (indoor) environment will be vastly different from the combined UV and weather exposure of an outdoor installation.

Degradation of polymeric materials (such as those typically used in electric cables) by exposure to solar radiation or light is by photo-oxidation.

Normally, for coloured materials, combinations of UV absorbers and light stabilisers are used to achieve some protection, but the main disadvantage is that the stabilisation effect decreases with time as the light stabilisers are continuously consumed. The use of carbon black as an UV light stabiliser has been the standard in polyolefin sheathing for communication and power cables. Such techniques have provided cables with sufficient stabilisation and protection for around three decades’ exposure to outdoor environments.

The cause?

BASEC says that under investigation, heat was originally thought to be the cause of the degradation, but the temperatures measured in the installations were not sufficiently high to do the damage behaviour by itself. In fact, the exposure of the cable to a combination of heat and UV is possibly a more significant reason for the dramatic degradation. The organisation is currently testing for this but ‘other factors could also be at play’, it says.

Where the installation is in a public building, which requires lights on 24-7, the effect of UV exposure could be accelerated, but another significant factor could be that LSHF cable had been specified for its performance in a potential fire situation, rather than for the application as a whole. Previously, these applications would have used materials that have a higher tolerance of UV exposure, like PVC, but which conversely produce smoke and other toxic products in a fire situation.

The cases of the degradation seen were within public buildings and involved modular lighting units installed around five or six years ago, although the UV effect might not be exclusively affecting modular systems. The cracked wiring was often found during routine maintenance and required remedial work or replacement of the affected cables.

Testing and standards issues

So what tests are required? The evaluation of the resistance to weathering of materials can be achieved through direct weathering outdoors, but for most purposes, says BASEC, it is more practical in economical and time consumption terms to assess material performance by exposure to artificial light sources that accelerate the degradation.

BASEC has been carrying out preliminary tests at its Milton Keynes laboratory, and is working with the Lighting Industry Association (LIA) on this issue. Furthermore, the organisation is seeking a test requirement for combined UV and heat degradation on cables to be introduced, possibly BS EN 50289-4-17:2011, which is for communications cables, or a similar test. Such a testing requirement needs to be included within appropriate cable standards.

As stated, the normal way to combat UV exposure is to use a black sheathing, but in most lighting applications the requirement is for white cables. Moreover, this approach is only a partial solution, as it does not remedy the issue of core insulation cracking where the sheath is stripped back for termination. A long-term solution could be to manufacture cables to existing standards and build in a UV test for both cores and sheath, with yet to be defined pass and fail parameters.

Currently, an amendment to Wiring Regulations BS 7671:2008 is being considered. This would require consideration of heat and UV effects when specifying cable for lighting applications. If this goes through, cable suppliers, says BASEC, will soon need to provide reassurance to users about this topic.

In the meantime, and until a suitable standard is published, architects and designers, contractors and electrical professionals should comply with regulation 522.11 of BS 7671:2008 which states: ‘Where significant solar radiation (AN2) or ultraviolet radiation is experienced or expected, a wiring system suitable for the conditions shall be selected and erected or adequate shielding shall be provided. Special precautions may need to be taken for equipment subject to ionising radiation’.

Note that when deciding whether cable should be replaced during a refurbishment, installers and end users should not just look at the cable as it is now, but consider the possibility of degradation and failure in the period before it is next likely to be assessed, which might be another 10 years. If a major refurbishment is underway it may be less disruptive to replace cables now, rather than take the risk.

Links

Read others news