A major cable recall affecting up to 40,000 homes and businesses and costing an estimated A$80 million dollars (£43m) has hit the headlines in Australia – and non-compliance is the issue, reports the British Approvals Service for Cables (BASEC).

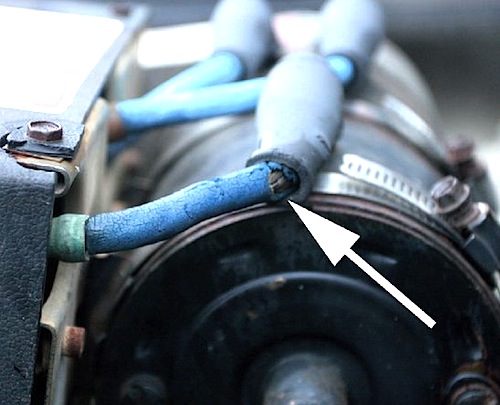

The insulation of electric cables used outdoors is well known to be prone to rapid degradation by ultra-violet (UV) exposure, so it is important that a type recommended for outdoor use be used. What is less well-known is that, even indoor cables, if mounted near to lighting systems (such as luminaires), can suffer from UV damage. The British Approvals Service for Electric Cables (BASEC), has just warned about this.

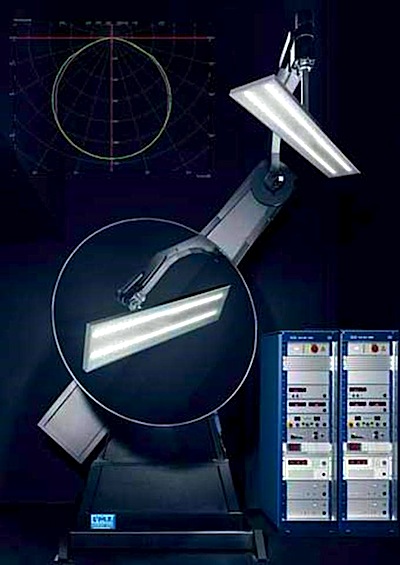

Joining the Lighting Industry Association’s (LIA) new and very modern Telford lighting test lab is another leading edge test facility being commissioned in Milton Keynes by the British Approvals Service for Cables (BASEC).

The brand new BASEC laboratory facilities in Milton Keynes, which are currently being commissioned, have been designed to meet the rising demand for Construction Products Regulation 2011 (CPR) fire tests on electrical cables.

Electrical Safety First’s recent roundtable on product safety, recalls and traceability, attracted a distinguished audience, comprising representatives from leading manufacturers, retailers and trade and enforcement agencies.

Today, the lighting industry is seeing exciting and dramatic changes, with new technological advances – mainly LED-based - arriving seemingly on an almost daily basis. This means that the demand for lighting testing is increasing fast, and one result is that the Lighting Industry Association (LIA) is planning a new, much larger and more advanced testing laboratory in Telford.

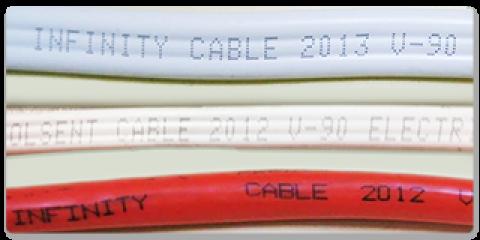

The British Approvals Service for Cables (BASEC) is encouraging cable manufacturers and traders to make more technical information readily available to users of their cable products.

Through its ISO 17025 accredited testing, verification and certification service, the LIA Laboratories provide lighting manufacturers with an independent ‘testimonial’ for their products, giving customers extra reassurance and peace of mind. The LIA laboratories work to build relationships with the supply chain from manufacturers and specifiers, to wholesalers and end users, meeting the needs of the lighting industry effectively.

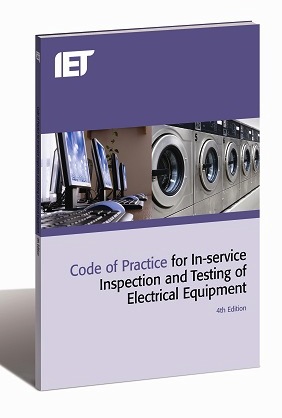

The UK Coalition Government believes that good health and safety is important, but that the burden of excessive health and safety rules and regulations on business has become too great. It claims that a damaging compensation culture has been stifling innovation and growth. It is this view that led to Professor Löfstedt’s report1 and the HSE view that promotes a proportionate risk-based approach when assessing the safety of electrical equipment and appliances, which is the reason behind the publication of the IET’s 4th Edition Code of Practice for In-Service Inspection and Testing of Electrical Equipment.

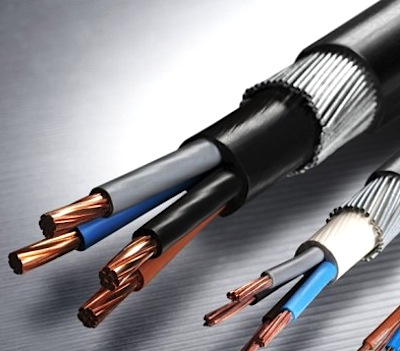

Most building fires are caused directly or indirectly by human error, but a significant number are caused by electrical equipment or installation failure, so cable fire properties are very important. The EU product standard for cables, EN 50575, will be published very soon. This means that all cable manufacturers intending to sell cables for use in permanent installations in European buildings will need to obtain CE-marking.

The publishing in February 2010 of the new BS 8519:2010 Code of Practice led to a number of misleading claims being made for some cables, according to Draka, with the confusion appearing to have arisen from a misinterpretation of the different test methods required for power and control cables.

European Harmonised cables are going to be removed from British Standards (BS 6004, BS 7211, BS 6500 and BS 7919), these will now be in the BS EN 50525 series. Also, certain requirements have been changed, as Graham R O’Geran, Operations Manager at BASEC.

2013-2026 © Doesitcomply UK. ALL Rights Reserved. Privacy Policy | Terms of Service